Redirect - Wireless Inductive System (WIS) Enables Wireless Sensor Connection

The application

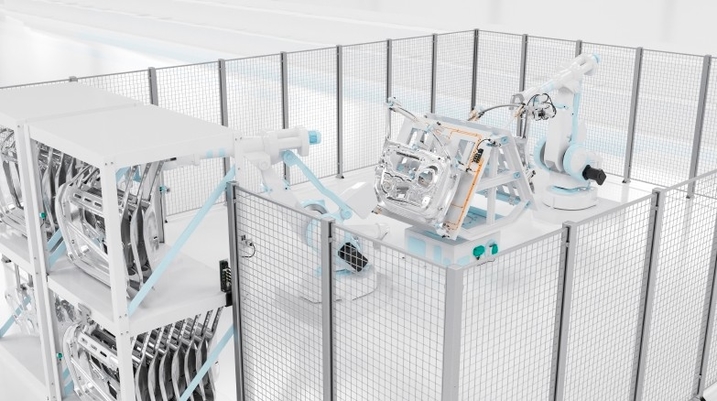

In the world of automated manufacturing, there is increasing demand for flexible solutions. One solution is the use of multi-tooling, a concept that enables the easy exchange of workpiece frames during production processes. Common in automotive manufacturing is the verification of door positioning prior to weld cell operations. In this case, multiple sensors are mounted on the removable workpiece frame while door position status information is communicated across a wireless boundary to the control system.

The goal

When there is a changeover to a different workpiece in the production process, the entire part-holding frame, including all of the attached sensors, is exchanged to accommodate the new production workpiece. In a traditional solution, connectors must be manually removed and reconnected to establish connection between the sensors and the fixed turntable. This changeover time increases cost, and the repeated connection and disconnection takes a toll on the connectors. WIS makes it possible to reduce changeover time and avoid this wear and tear by allowing non-contact, wear-free sensor connectivity.

Enabling noncontact connectivity where no fixed connections are possible: the new Wireless Inductive System

The solution

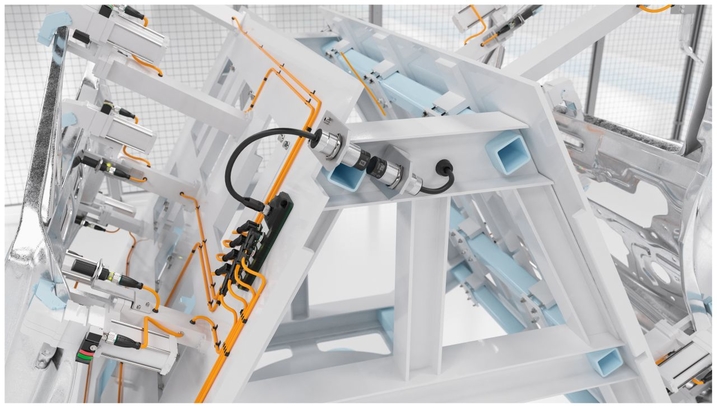

WIS transmitters can be combined with 8-socket junction blocks for efficient and space-saving solutions.

The wireless connection system is used to supply power to the sensors on the workpiece frame and to transmit signals from sensors to the control system, reducing the connection complexity. The WIS portfolio includes an eight-channel version for transmitting up to 8 sensor signals and a two-channel version for applications with one or two sensors. Both versions allow power transmission up to 12 W and power and sensor signal transmission over a distance of up to 7 mm—making WIS perfect for high-power, high-vibration applications where consistent alignment is critical.

The benefits

The WIS system is ideal for a variety of applications where it is necessary to frequently connect and disconnect sensors. In applications with moving machine parts or part holders where wiring is burdensome or not possible, it provides a cost-effective, reliable alternative to drag chains or slip rings and helps prevent contact problems, cable breaks, and sparking.

At a glance

- Optimized performance for demanding applications with up to 12 watts power transmission

- Wider tolerance to axial misalignment with up to 7 mm transmission distance

- Multiple application possibilities and flexibility due to compact 2-channel and expanded 8-channel versions

+61 3 9358 3400

+61 3 9358 3400