Automatic Recording and Ordering in the Kanban System

The RFID system detects containers and allows the assignment of content

The Application

The Kanban system has established itself as a highly efficient control tool for the assembly of complex products. Its “pull” concept simplifies demand-based production planning. At the same time, the system acts as a central element of intralogistics in which different parts are flexibly assembled into a wide range of components. This makes it possible to set up flexible assembly units that are divided into small sections and can perform their work without a separate supply of raw materials.

The Goal

In many operations, replenishment requirements are recorded using routing slips and visual inspection. The goal is to automate this step. A sensor must indicate whether containers with the correctly assigned material are present in the rack. Any incorrect assignment must also be recognized as such. Automatic detection ensures the efficient, reliable redelivery of materials and ensures processes run smoothly.

The Solution

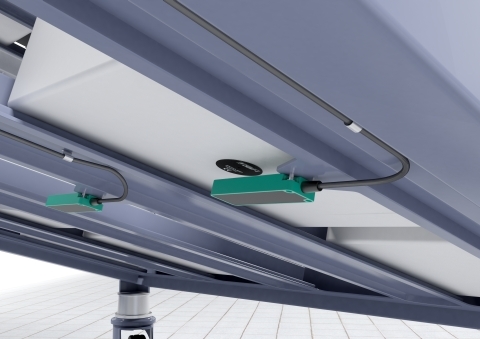

IQH1-F61-V1 RFID read/write head

The Kanban containers are equipped with RFID tags to enable reliable identification. These tags are detected by RFID read points that are integrated into the racks. The flat IQH1-F61-V1 read head is particularly well-suited to this task. It identifies the raw material containers to which specific content is assigned in the system. This capability virtually eliminates errors in the sorting of containers. Regardless of the position of the container, it is possible to check whether a sufficient quantity of the required parts is held in stock.

Technical Features:

- Operating frequency 13.56 MHz

- Complies with ISO 15693

- Flat IQH1-F61-V1 RFID read/write head

- Connection cable with V1 plug (M12 x 1)

- IP67 rating

- Suitable for mounting on metal

- For connection to the IDENTControl control interface

The Benefits

With its flat and compact design, the RFID read/write head can be easily integrated into the racks of Kanban systems. It reliably records the information on the tag and is unaffected by the metal structure of the racks. Its signals are fed to the control system via common bus and communication systems such as PROFINET. The containers are registered during replenishment, which automatically prevents incorrect sorting. The same applies if there is no longer a sufficient number of containers with a certain part. The replenishment request is then triggered automatically.

At a Glance

- RFID tag allows the identification of individual Kanban containers

- Compact IQH1-F61-V1 RFID read/write head for installation in metal racks

- Clear assignment of containers and content prevents incorrect sorting

- Efficient and reliable redelivery of materials ensures a continuous process without interruption

- Data from inventory monitoring is available for logistics management at all times

+61 3 9358 3400

+61 3 9358 3400