Reliable Detection and Securing of Hose Connections

RFID Solution Prevents Incorrect and Missing Connections

The Application

Hoses allow flexible connection, for example, between a portable tank and a fixed tank. They are regularly used to transport liquid substances in processing plants for the chemical and pharmaceutical industries, and for the food and beverage industry. To ensure the integrity and safety of processes and to provide quality assurance, it is essential that the hoses connect only the intended end points together and that this connection is reliable. An incorrect or unestablished connection may result in safety problems, production downtime, the need for extensive cleaning, or damage to the plant. If the process is compromised due to incorrectly connected or disconnected hoses, there may be expensive consequences.

The Goal

It is essential to avoid incorrect or missing connections. This goal requires reliable, automated identification of the hose connections at their end points. The intention is to ensure that substances cannot be incorrectly fed or accidentally released. When filling tanks, the connection of a hose to the wrong process medium needs to be detected immediately so that an appropriate block can be triggered. The intention is to also prevent pump activation or process start-up, if the correct connection at both ends of a connected hose is not guaranteed.

The Solution

IQH1-18GM-V1 read/write head

RFID read/write heads are mounted on the hose couplings. Each end of the hose features an RFID tag. The tags are written with identification-related data such as the hose number. Based on the signals from the read heads, the control software detects whether a desired, correct connection has been established with the hose. If this is not the case, the medium is not conveyed, or the process is not started. The corresponding valve will be blocked if an incorrect connection is detected. Accidental filling of tanks that are already full is prevented by adjusting the RFID signals to the level measurement.

IQH1-30GM-Ex read/write head

Technical Features:

IQH1-18GM-V1 read/write head

- Especially compact design

IQH1-30GM-Ex read/write head

- Variant for use in hazardous areas

IQC21-12 or IQC21-16 tag

- Rugged design

- Can be flush-mounted in metal

The Benefits

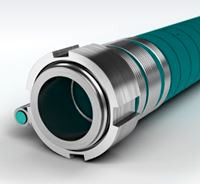

RFID read/write head flush-mounted in the metal protective shroud

Small and rugged RFID read/write heads can be flush-mounted in the metal protective shroud on the hose coupling. Rugged, compact tags are likewise available for the hose ends. Both products are available in chemically resistant versions, and the read heads are available with explosion-protection approval. Alongside its actual task, RFID data can be used for inventory, servicing, and predictive maintenance. The data allows individual hoses to be specifically inspected according to the frequency of use. A damaged hose can be identified as such in the database. This means that it is detected and blocked in the event of accidental use.

At a Glance

- Automated identification of hose connections

- Protection of process integrity, prevention of damage and consequential costs

- Rugged system, with explosion protection if required

- Chemically resistant components available

- Data can be used for inventory and predictive maintenance

+61 3 9358 3400

+61 3 9358 3400